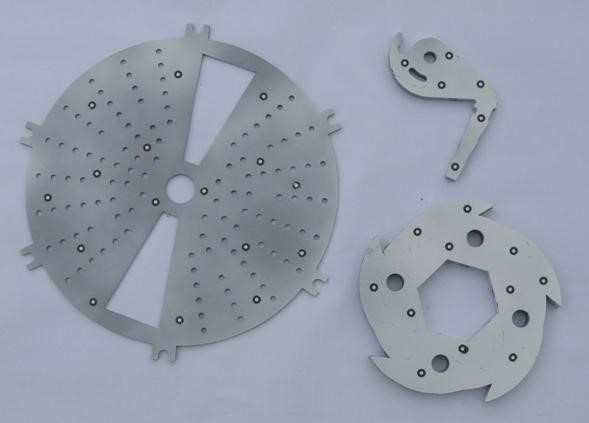

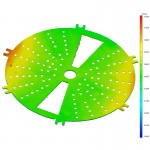

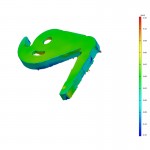

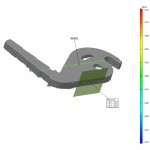

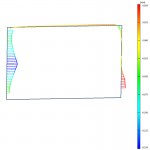

We offer our customers 3D optical measurements in order for them to make sure of the quality of the cut. According to their wishes we perform a measurement and set up a protocol of the cut part.

With optical measuring systems manufactured by GOM we are able to control the shapes and dimensions of the entire product or its individual parts. The volume measured can be adapted, ranging from a few millimetres to several metres. The measurement accuracy can amount to 0.005 mm (5µm), depending on the size of the object in question. The system enables: